Lead melting equipment single stage gas burner

Informação básica

Modelo: HJ-Series

Descrição do produto

Lead melting equipment single stage gas burner

Summary of the gas burner

Coal gas furnace (gas burner )uses coal or coke,carbon material as fuel, air and water vapor are mixing for gasification agent in a gasification process.Using the automatic coal feeding, automatic slagging, the unique pagoda type heat-resisting cast steel grate,which has powerful broken slag, slag loosening, breathable function. No smoke in the burning process,concentration of sulfur dioxide and soot emissions are in line with environmental standard GB9078- 1996. Many coal gasifier advantages,such as,Reasonable gas gasification,simple design,lower investment,safe and convenient operation,simple operation and maintenance,which are well received by customers praise,this is my company launched a new area of intelligent and efficient energy-saving environmental protection products.

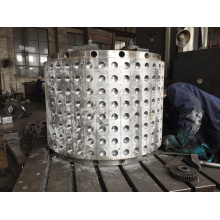

Detailed pictures of gas burner

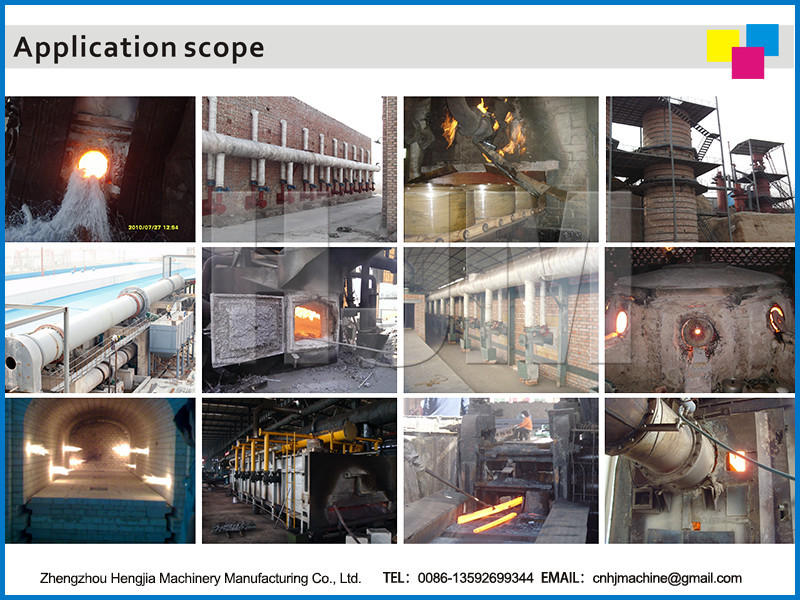

Customer site of gas burner

Application of gas burner

Characteristics of the gas burner :

1.The gasifier equipe the bucket to left coal, double bell jar feeding mechanism, and better the sealing effect, its adjustable pocket flap and conical coal unit can be used combinable, coal distribution uniformity.

2.Basically same thickness in cross-section fuel, so as to improve coal gasification efficiency, put an end to occur the flaming phenomenon of partial furnace.

3.The furnace adopts full water jacket, self-produced steam, not outside for steam, pressure stability, favorable gasification in hearth, good cooling effect in furnace, water jacket inner sleeve deformation.

3.Double bell coal feeder bring better sealing.

4.Wet rotary ash disk system adopt a tower type pyramid pentagonal grate,material is made by the steels casting.Design of small ash knife push slag, which add the mechanism of slag,broken slag structure,which enable uniform distribution and operation of gasifying agent.the material layer in the distribution is relatively stable, in the best gas state, and reduce the carbon content of slag, to solve the traditional gasification furnace in order to prevent coking frequent tie brazing, throw the problem of fire;this structure can make the agency distribution uniformity,current operation uniform slag,furnace is relatively stable the best state of gas,reduce the carbon content of slag, and have solved the traditional gasifier in order to prevent coking frequent fire drill and flaming out.

5.With isolation of water seal dust catcher, during the outage boiler stop, which can improve water closed height, cut off the gas generator and thermoelectrical furnace between gas and make sure have no pressure, put an end to happen the tempering explosion.

6.With refractory concrete roof insulation,cooling water saving.

7.Use the special burner, this gas furnace are based on different specifications, different using conditions, equipped with a special "ejector type" burner, which can bring some usages, such as sufficient fuel combustion, stable operation, long life and other characteristics.

Technical parameters of the gas burner

Item |

unit |

Model and specification |

|||||||

HMCQ-8 |

HMCQ-10 |

HMCQ-12 |

HMCQ-16 |

HMCQ-20 |

HMCQ-26 |

HMCQ-32 |

HMCQ-3.4 |

||

Chamber diameter |

mm |

800 |

1000 |

1200 |

1600 |

2000 |

2600 |

3200 |

3400 |

Hearth area |

m² |

0.5 |

0.785 |

1.13 |

2.01 |

3.14 |

5.31 |

8.04 |

9.08 |

Fuel layer |

mm |

1000 |

|||||||

Fire layer |

mm |

100~300 |

|||||||

Ash layer |

mm |

100~300 |

|||||||

Applicable coal |

Non-caking or weak-caking anthracite, bituminous coal, etc. |

||||||||

Coal size |

mm |

13-25, 25-50 |

|||||||

Coal consumption |

Kg/h |

40-100 |

70-140 |

120-190 |

350-460 |

500-720 |

850-1200 |

1800-2200 |

1900-2600 |

Gas catalyst |

Air, steam |

||||||||

Gas output |

Nm³/h |

140-350 |

245-490 |

420-670 |

1200-1600 |

1750-2500 |

3000-4300 |

6500-7500 |

7000-8000 |

Net heating value |

KJ/Nm³ |

5020-5670(related to the coal) |

|||||||

Steam production |

Kg/h |

60 |

80 |

130 |

220 |

300 |

500 |

550 |

650 |

Gas temperature |

°C |

300-550 |

|||||||

Coal gas pressure |

Pa |

980-1470 |

1470-1960 |

||||||

Hot blast pressure |

Pa |

<3000-4000 |

<6000 |

||||||

Saturated temperature |

°C |

50-65 |

|||||||

Ash tray speed |

R/h |

0.177-1.77 |

|||||||

Whole power |

Kw |

<6 |

<6 |

<6 |

<8 |

<8 |

<8 |

<10 |

<10 |

Why choose our gas burner

1.Safe and pro-environment

2.Evenly combustion, save 20% fuel

3.Advanced gasifier technology

4.High heat value .

5.Easy to operate&maintain

6.Long service life

Shipping on-site of gas burner

Certification of Zhengzhou Hengjia Machinery

About Zhengzhou Hengjia Machinery

Zhengzhou Hengjia Machinery Manufacturing Co. , Ltd. is a joint-equity enterprise, which is specialized in research and development, producing and manufacturing of all kinds of drying machinery and energy conservation and environmental protection heat source.

The dryer developed by our corporation for the drying of coal slime, sludge, saw dust, sand, coal ash, flue gas desulfurization gypsum, sprayed corn bran and all kinds of food and mining industry has professional technical ability and distinguished product performance and sell very well in more than 30 provinces of China, also in abroad, like Russia, Korea, Vietnam, India, Malaysia, Indonesia, Pakistan and so on.

About us

1. We are Factory (Not Dealer)

All machineries from Zhengzhou Hengjia Machinery Manufactory are made by ourselves, with lower price, good quality and assured full after service. So please buy machine from our factory.

2. Training & Service

♥ Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacture equipment according to your special demand.

♥ Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

♥ After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

♥ In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.

3. If you are new for this business, we will help you

Many thanks for your trust; we can provide you with design scheme for complete production lines, spot inspection and operator training according to your demands and the conditions of applied spot, we can help you choose the right equipments.

4. We’d like torecommend a suitable type for you and send you a best quotation. Some questions please inform us in your enquiry.

♥ Could you tell us the calories you need?

If you have any other questions about our products, you may contact Lisa through skype: lisa.hjm

Looking forward to your kind inquiry and welcome to visiting our factory!

Grupo de Produto : Equipamento de gaseificador > Gaseificador de carvão

Premium Related Products