New type triple pass rotary drum dryer manufacturer for coal/fly ash/slag

Informação básica

Modelo: HJRD300

Descrição do produto

New type triple pass rotary drum dryer manufacturer for coal/fly ash/slag

Summary of triple pass rotary drum dryer:

Among the serials of products of wet-material drying equipment, three-cylinder dryer is a modified high efficiency and energy saving product based on single-tube rotary dryer. It has been used in many enterprises and industries, which proves that it has a good effect. The inner structure of three-cylinder dryer has been modified on the basis of single-tube rotary dryer, which increases the pre-drying time of wet materials before they enter the machine and the drying time in the machine. Besides, with seal, moisture preservation and other supporting measures, the production capacity of three-cylinder dryer has increased 50-80% compared with that of single-tube dryer, the evaporation intensity of every unit volume can reach 120-180kg/m3, and the standard coal consumption is only 6-8kg/t. It has modern technology, reasonable operation parameters and simple operation.

Photos of triple pass rotary drum dryer:

cyclone dust remover:

Inner side:

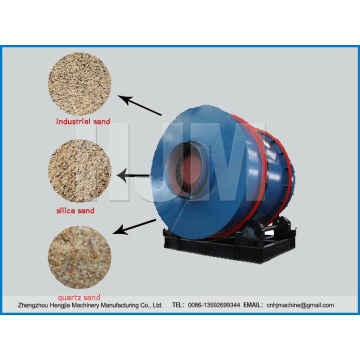

Application of triple pass rotary drum dryer:

It can be used to dry slag, clay, coal, iron powder, mineral powder and other admixture, as well as dry-mixed mortar, yellow ground and the like of construction industry, and also the raw material of industries like chemical engineering, casting and so on.

The structure of triple pass rotary drum dryer and its operating principle:

The main body of three-cylinder dryer is made up of three concentric circles of different diameters one inside another. It is placed horizontally on the riding wheels at the two ends through tyres, which are actuated by the reduction gear drove by two electric motors, thus the cylinder of dryer can rotate around the axle uniformly and steadily. The material first enters into the internal cylinder, then turns into the middle cylinder, then the outer cylinder, and outside at last. Since sleeve type is used, the length of cylinder is greatly shortened. Compared with the floor area covered by the single-tube dryer of the same specification and model, that of three-cylinder dryer can be decreased by 50%. The structure of sleeve type contributes to self heat preservation. Heat energy emitted by the internal cylinder during working is absorbed by the middle cylinder, similarly, that emitted by the middle cylinder is absorbed by the outer cylinder, thus heat energy can be fully absorbed, so heat efficiency can reach 80%, while that of single-tube dryer is only 35%. Because the material has a long journey to go in a single-tube dryer, the heat consumption can’t get effective use, thus the drying cost is high. So comparatively, the efficiency of three-cylinder dryer has increased by 45%.

Model Specification |

φ2*4.5m |

φ2.2*5m |

φ2.5*6m |

φ2.7*6.5m |

φ3.0*6.5m |

φ3.2*7m |

φ3.6*8m |

φ4.2*8m |

Diameter of Outer Cylinder(m) |

2 |

2.2 |

2.5 |

2.7 |

3.0 |

3.2 |

3.6 |

4.2 |

Length of Outer Cylinder(m) |

4.5 |

5 |

6 |

6.5 |

6.5 |

7 |

8 |

8 |

Cylinder Volume(m3) |

14.13 |

18.99 |

29.43 |

37.19 |

45.92 |

56.27 |

81.39 |

110.78 |

Revolving Rate(r/min) |

4~10 |

|||||||

Temperature of Inlet Air (C°) |

180 C°~800C° |

|||||||

Yield Production(Ton/Day) |

13~18 |

15~23 |

20~28 |

24~33 |

35~40 |

40~60 |

55~75 |

70~120 |

Engine Power(KW) |

5.5*2 |

7.5*2 |

5.5*4 |

7.5*4 |

11*4 |

15*4 |

18.5*4 |

22*4 |

Remarks |

Besides the above models, we can also supply special models as your request. |

|||||||

Working principles of rotary dryer:

About Zhengzhou Hengjia Machinery

Zhengzhou Hengjia Machinery Manufacturing Co. , Ltd. is a joint-equity enterprise, which is specialized in research and development, producing and manufacturing of all kinds of drying machinery and energy conservation and environmental protection heat source.

The dryer developed by our corporation for the drying of coal slime, sludge, saw dust, sand, coal ash, flue gas desulfurization gypsum, sprayed corn bran and all kinds of food and mining industry has professional technical ability and distinguished product performance and sell very well in more than 30 provinces of China, also in abroad, like Russia, Korea, Vietnam, India, Malaysia, Indonesia, Pakistan and so on.

1.what is the raw material?

2.what is the moisture before drying and after drying?

3.what is the capacity per hour?

4.Heat source? (firewood,coal ,heat gas ,electricity)

5.Where the final dry material used for ?

If you are interested in our rotary dryer, please kindly contact with us~

Skype: lisa.hjm

WhatsAPP:+86-18317887657

Tel: +86-371-67845338

Grupo de Produto : Secador equipamento > Secador giratório

Premium Related Products